Speed Reducer Gearbox for Space Entrepreneurship

Introduction

In the innovative field of space entrepreneurship, the utilization of cutting-edge technologies is crucial for success. One such technology that plays a significant role is the speed reducer gearbox. This article aims to explore the functions of a reduction gearbox, the difference between a speed reducer and a gearbox, and provide insights into selecting and customizing the appropriate gearbox for specific requirements.

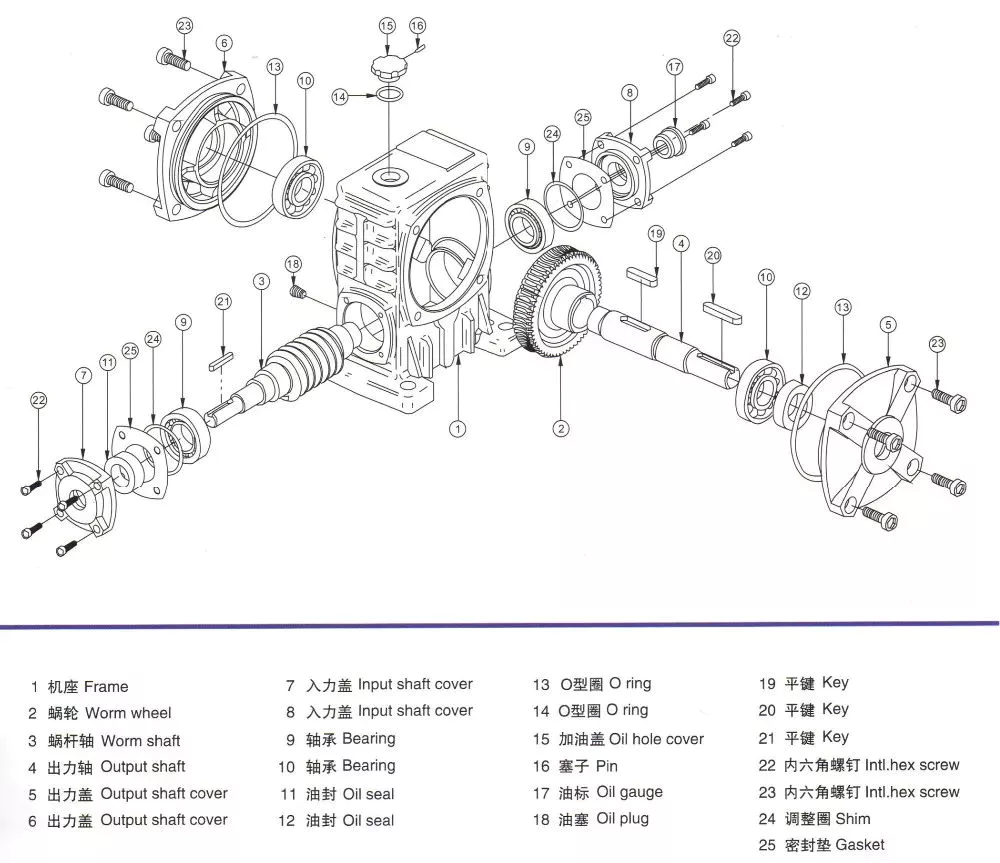

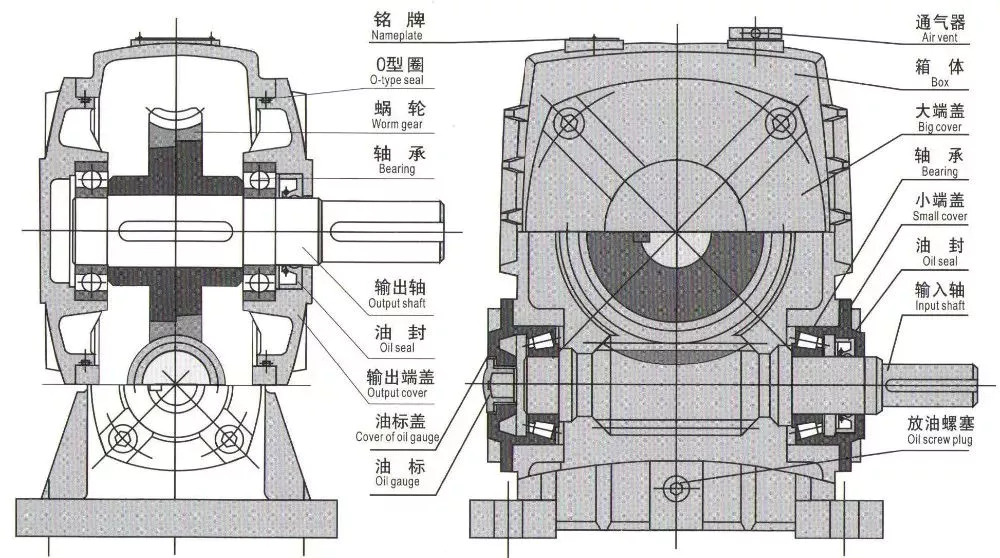

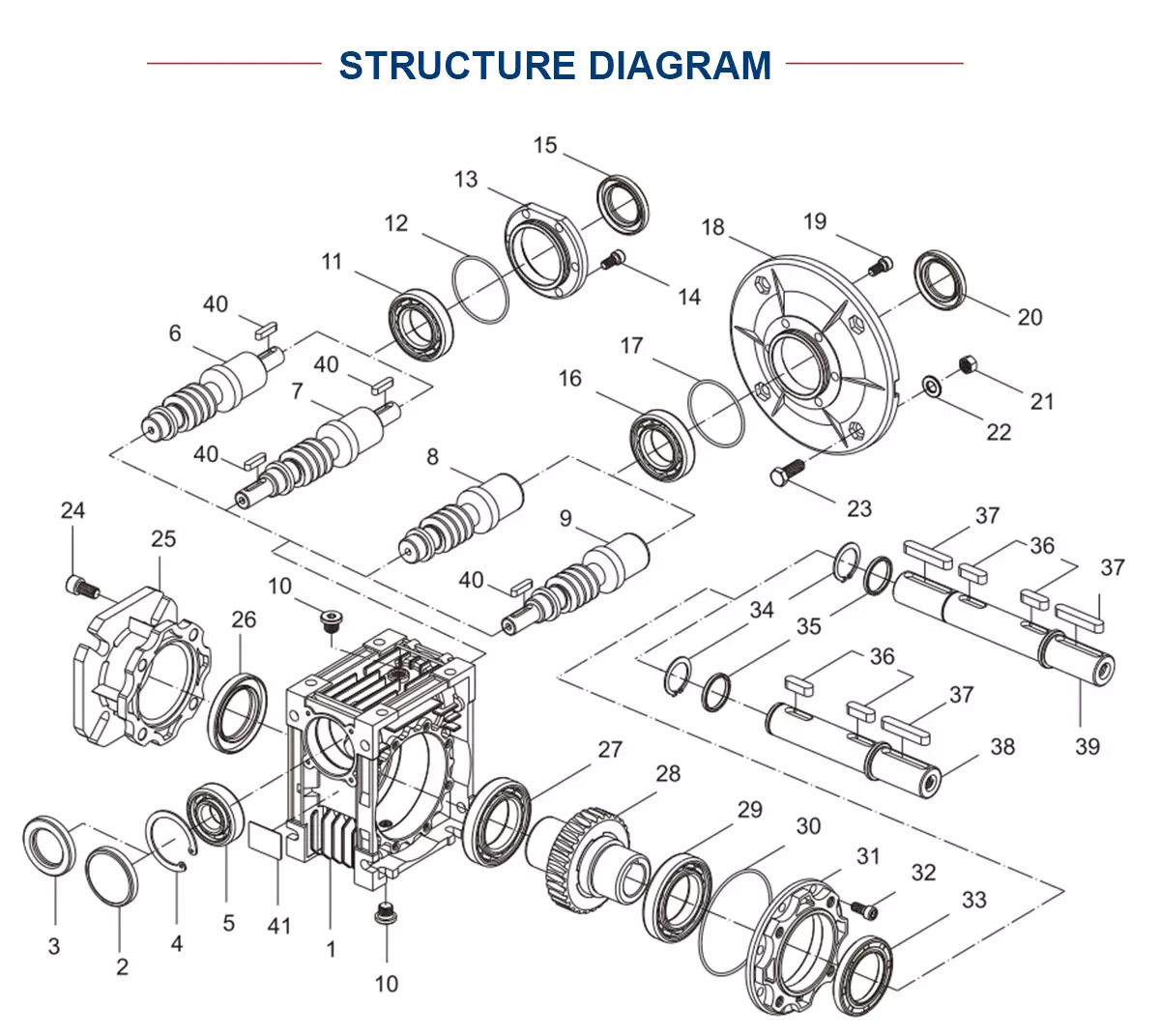

Functions of a Reduction Gearbox

- Power Transmission: A reduction gearbox efficiently transfers power from the input to the output shaft, enabling the smooth operation of various space exploration equipment.

- Torque Amplification: By reducing the speed and increasing the torque, a reduction gearbox ensures the necessary force for heavy-duty applications, such as launching satellites or maneuvering spacecraft.

- Noise and Vibration Reduction: The gear arrangement within the reduction gearbox minimizes noise and vibration, maintaining a stable and controlled environment for space missions.

- Speed Regulation: With adjustable gear ratios, a reduction gearbox allows for precise speed control, facilitating the optimization of spacecraft maneuvers and operations.

- Protection and Safety: The reduction gearbox serves as a protective barrier, shielding sensitive space exploration components from external factors like shocks, impacts, and extreme temperatures.

The Opposite of a Reducer Gearbox

The opposite of a reducer gearbox is a multiplier gearbox. While a reducer gearbox decreases speed and increases torque, a multiplier gearbox does the opposite by increasing speed and decreasing torque. In certain space entrepreneurship applications, where high speeds and low torque are required, a multiplier gearbox may be employed.

Difference Between Speed Reducer and Gearbox

The term “speed reducer” is often used interchangeably with “gearbox,” but there is a subtle distinction between the two. A gearbox refers to a system that contains various gears and shafts to transmit power and modify speed, torque, and direction. On the other hand, a speed reducer specifically focuses on reducing speed while increasing torque.

Selecting and Customizing the Suitable Gearbox

Choosing or customizing the right gearbox involves considering specific parameters and practical conditions. The following points highlight key factors for selecting an appropriate gearbox:

- Load Requirements: Analyze the required torque, speed, and power to ensure the gearbox can handle the anticipated load.

- Environmental Conditions: Assess factors such as temperature, humidity, and vibration levels to determine the gearbox’s durability and suitability for the space environment.

- Space Limitations: Consider the physical constraints and available installation space to ensure the gearbox fits properly within the designated area.

- Efficiency and Precision: Evaluate the gearbox’s efficiency and precision in power transmission to maximize overall system performance.

- Maintenance and Reliability: Take into account the gearbox’s maintenance requirements and reliability to minimize downtime and ensure continuous operation.

About HZPT

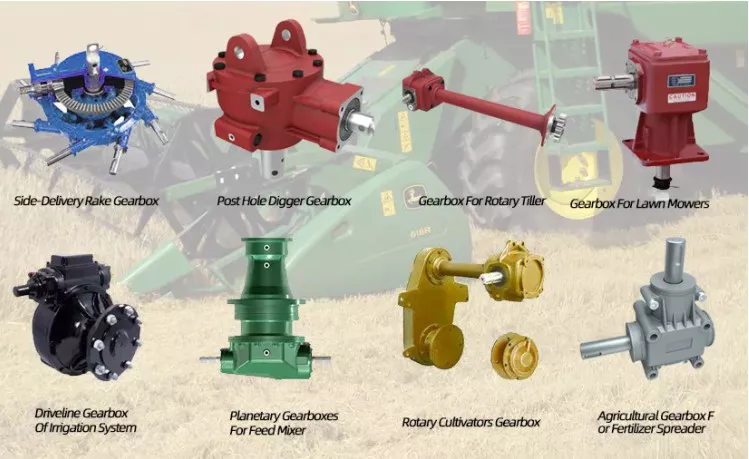

Founded in 2006 and located in Hangzhou, China, HZPT specializes in the production and sale of high-quality gearboxes. Our vast product portfolio comprises over 10 series and thousands of specifications, including planetary gearboxes and helical bevel gearboxes. With four patented technologies, we excel in manufacturing high-torque, precision customized reducers. As a leading provider of gearboxes, we offer a wide range of advantages:

- 20 years of ODM and OEM experience, ensuring top-notch quality and tailored solutions.

- 100% pre-shipment testing to guarantee the reliability and performance of our gearboxes.

- 24/7 customer service, ready to address any inquiries or concerns promptly.

- Utilization of the finest materials and regular product design updates to meet market demands.

- Factory-direct prices, ensuring cost-effectiveness for our customers.

For customized, OEM, or ODM requirements, HZPT gladly accommodates packaging and branding preferences. We take pride in our professionalism, exceptional customer service, and dedication to delivering top-quality gearboxes. Contact us today, and we will respond within 24 hours.